RG Gold progressing well with 5Mtpa CIP Plant construction

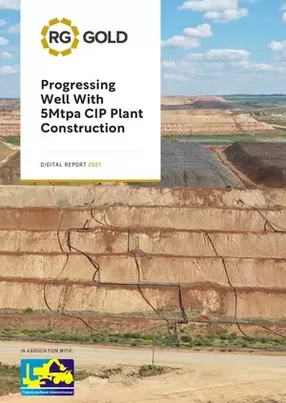

RG Gold, the Kazakh gold mining and production company, operates one of the largest deposits of gold in Kazakhstan and is the third largest in terms of gold resources. The deposit is in the Burabay area of Akmola region, covering an area of 67.7 sq. km that consists of two pits: North and South.

RG Processing, set up in October 2018, was created to facilitate the engineering and design of the project for the construction of a carbon-in-pulp (CIP) plant, that is expected to start processing 5 Mtpa of sulfide ore from Q3 2022. The KZT180 billion project includes building all necessary infrastructure objects such as tailings facility, new camp, water supply facilities and a new HV powerline.

Both companies’ shareholders – Kazakh private equity group Verny Capital and American group of private equity funds under common management Resource Capital Funds (RCF) – are actively involved into companies’ strategic and operational management.

Rossouw’s attention is now firmly fixed on the getting the new mine up and running. It is targeting 5 tonnes of gold per year, with 170 tonnes in resources and 99 tonnes in reserve.

The total construction cost is $425 million. Development Bank of Kazakhstan JSC (a subsidiary of Baiterek Holding) provided a loan in the amount of up to US$300 million for nine years and the remainder will be provided by RG Processing at its own expense.

“We brought AAEngineering Group on board in January,” explains CEO Lawrence Rossouw. “They are the major technology-EPC provider at the moment, and they will also be responsible for commissioning services in the ramp up to full production. It’s been challenging, especially with the COVID situation. Some items got stuck at the Chinese border for several months, and that was frustrating. We had to re-organise our construction schedule to accommodate the late delivery of these items.”

Bullion will be sent to the Kazzinc refinery. Kazzinc operates one of the largest gold producing operation in Kazakhstan, Altyntau Kokshetau in the Akmola Region.

Alongside the new venture, RG Gold is busy maximising its 2mtpa oxide ore treatment facility which it has been operating for the last 9 years.

“The aim is to keep running that plant for the next two to three years. While we’re ramping up the CIP plant, we will have this plant in production as well. So, from 2023-25, we will be treating 7mtpa in total across both plants,” he adds. “Drilling results looks really good. We are expecting additional oxide resources close to surface, so the potential exist to keep the Heap Leach operation running for several years, maybe even longer.”

Currently its workforce stands at 920 across mining, geology, processing and administration, but the plan is to add another approximately 300, to operate the CIP plant, growing total manpower to around 1,250 by the middle of next year.

“We’ve been very fortunate in that COVID hasn’t impacted our business in any severe way. We obviously applied the strictest preventative measures and protocols, it was costly, but it was worth it – and we weren’t affected from a production point of view, and the project team worked remotely.”

In terms of partners, RG Gold works closely with ASPMK, which has installed a new, 75km high-voltage overhead line, which will be commissioned in October this year; CPS, which built the tailings storage facility, and should be finished by the end of the year; and Fortinet protects its IT infrastructure.

“We’ve built up a lot of connections with other mines – we collaborate with Kazzinc and Altynalmas to use their operating facilities to train our people. They have processing plants similar to ours in terms of technology and throughput. We have an unofficial agreement with these companies that from March 2022, we will send personnel to their facilities for practical training purposes.”

The company prefers to use firms in Kazakhstan – since Verny Capital is a local entity – but it does call on international assistance when needed.

“We start local, the villages around us, and that’s where the majority of our workforce come from. Training is a massive challenge. We spend a lot of time and money getting qualified people.

“We’ll use partners when the quality of service locally isn’t to international standards – AMC in Australia handle mine design and geological work, for instance.”

At a time when many firms are rapidly embracing new technologies during the digital transformation, RG Gold is taking a measured approach. Construction design was completed using 3D modelling.

“In future, when we have an operating mine, we’ll use the new technology such as AI to manage the plant and monitor the processing parameters. Those will be implemented as we go forward. But right now, the focus is getting the plant up and running in a short period of time, as the timeframe is very aggressive.”

While the gold price may remain volatile, Rossouw is confident in the market’s future. “At least in the next 10 years, I see a big future for gold.