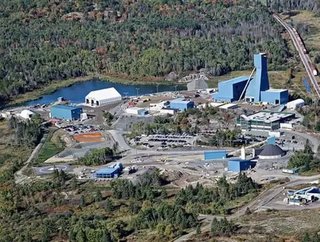

Inside Vales First New Sudbury Mine in More than 40 Years

The Brazilian mining corporation Vale has officially opened the doors to its Totten mine in Ontario’s Sudbury basin. The new base metals mine is Vale’s first in the area in more than 40 years.

The $760 million project took seven years to complete and will represent a significant investment in the future of Vale’s operations in Ontario and across Canada.

The mine – which Vale calls ‘Canada’s mine of the future’ – provided work for 500 people during construction and will employ 200 during the production base. The mine will produce copper, nickel and precious metals over the next 20 years and

"The opening of Totten Mine reinforces the strong confidence we have in our world-class base metals assets to deliver sizeable value through all commodity cycles. Vale is committed to its future in Canada and across base metals and we are pleased to be able to celebrate this historic milestone for our company and the Greater Sudbury community," said Peter Poppinga, President & Chief Executive Officer of Vale Canada and Vale's Executive Director of Base Metals and Information Technology.

"Totten Mine is Vale's first new mine in the Sudbury Basin in more than 40 years and represents a significant investment in the future of our operations in Ontario and across Canada,"

The Totten mine will feature the latest in mine technology and safety automation. Vale is implementing an array of innovative new programs, including a wireless underground communication system and location tracking on mechanical and personal protective equipment.

- Brightstar, Eldridge and Claure acquire AusencoSupply Chain & Operations

- First Quantum contracts with MECS to cut emissionsSupply Chain & Operations

- Tin production at Andrada Mining reaches record levelsSupply Chain & Operations

- Ternium plans to build US$3.2bn steel plant in MexicoSupply Chain & Operations