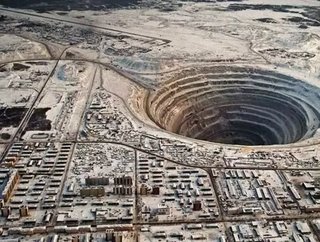

[VIDEO] Second Largest Excavated Hole in the World - Mir Diamond Mine

What started out as a small discovery in 1955 by Soviet geologists has transformed into one of the largest excavated holes the world has ever seen.

The open-pit Mir mine, located in Eastern Siberia, was once one of the largest diamond mines on earth, reaching depths of 1,722-feet and stretching 3,900-feet in diameter.

The former mine began production in 1957 and lasted 44 years until it was permanently closed in June 2001. During its peak years of operation, the mine produced 10 million carats of diamond annually. The Mir mine was originally owned by the USSR until the 1990s when it was operated by the Sakha diamond company. Later, the mine was operated by Alrosa, the largest diamond producing company in Russia.

Over time the history of the Mir mine has reached mythical proportion. The government had to restrict airspace above the mine because of alleged incidents of helicopters falling due to air temperature differences and unexpected currents.

- Brightstar, Eldridge and Claure acquire AusencoSupply Chain & Operations

- First Quantum contracts with MECS to cut emissionsSupply Chain & Operations

- Tin production at Andrada Mining reaches record levelsSupply Chain & Operations

- Ternium plans to build US$3.2bn steel plant in MexicoSupply Chain & Operations