[VIDEO] The History and Process of Silver Mining

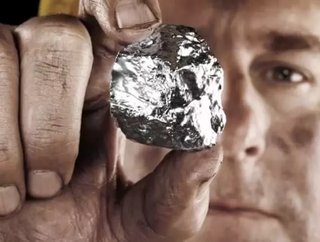

While the search for silver dates back as early as the 4th millennium B.C. it wasn’t until the mid-15th century when the precious metal began to be extracted in massive quantities. Today, more than 671 million troy ounces of silver are mined around the world annually.

The video below reveals the silver mining process as shown at the Silver Valley mining complex in northern Idaho.

The process of mining for silver

The process of mining for silver is broken down into three steps: removing ore from the earth, breaking it down and then flushing the silver from ore. The first step involves drilling holes in the silver-rich areas geologists have previously pinpointed and then inserting dynamite sticks. After the blast, miners haul the chunks of rock called ore to the surface. The geologists then test the ore piles and blend them as required to achieve a consistent amount of silver content per kilogram of ore.

Crushing ore

The ore first goes into the primary crusher, breaking up the big chunks into smaller pieces which then go down into a secondary crusher that breaks it down into smaller pieces. Those pieces then go into a vibrating cone crusher which pulverizes it into tiny pieces. A conveyor then transports the crushed ore to a ball mill, which grinds the ore into powder. A water circulation system flushes the silver rich powder out of the cylinder and into larger tanks. Worker then pour acid in to separate and dissolve the various metals the powder contains.

The dissolved silver is then pumped through filter presses and filter plates are treated with a zinc-based chemical that attracts silver molecules. The plates trap particles containing silver, forming a layer of black powdered called silver precipitate, which is composed of 50 percent of silver and 50 percent of waste.

Recovering the silver

To separate the silver from the waste, miners dry the precipitate in a gas furnace for a few hours while continuously testing ore samples to determine the grade. The samples are then heated to 1093 Celsius to burn off the impurities, leaving the silver and other metals such as lead, zinc and copper remaining. Lab technicians then treat the samples with a chemical that prevents the remaining silver from burning off. The sample is then inserted back into the furnace.

After about an hour, once all the other metals have burned off, the only thing left is silver.

- Top 10 most expensive precious metalsSupply Chain & Operations

- Silver market to hit deficit this yearSupply Chain & Operations

- Canada’s GSilver resumes mining operations at VMC in MexicoSupply Chain & Operations

- Silver Mines mineral resources at Bowdens Silver ProjectSupply Chain & Operations