The World of Gypsum

Since 1956, Harrison Gypsum has been a prominent figure in the gypsum mining sector. The company has made a name for itself by maintaining a consistent and high level of product quality. They operate four gypsum mines in Oklahoma, one mine in North Texas and three limestone mines – two in Oklahoma and one in South Kansas. The company also operates a number of hard rock quarries and pits in South Texas.

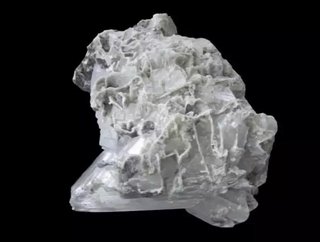

Used as a soil amendment in agriculture and calcined to manufacture plaster, gypsum is a soft sulfate mineral - calcium sulfate dihydrate. The use of gypsum is prevalent in the oil and gas industry in Oklahoma and North Texas as a road aggregate, is the major component of wallboard and other building products, and is commonly used as a calcium additive for yeast food products like bread.

Harrison Gypsum has developed into one of the largest producers and suppliers of gypsum in the United States by integrating a family-oriented approach, careful acquisitions and continual investments in mining equipment and infrastructure.

From the beginning

Born and bred in Oklahoma, the Harrison Gypsum Company started from humble beginnings. The mining company, which originally formed under the name Cement Gypsum Company, started as a small family operation supplying gypsum to local neighbors in the community. Commencing its first mine (Mine No.1) in 1955, the company changed its name in 1956 to reflect its overall commitment to the mineral.

Along with a family-oriented approach to business, Harrison Gypsum believes pursuit of consistent quality leads to cost effective mining and operational efficiencies. This dedication to quality and efficiency has aided Harrison Gypsum in becoming one of the top gypsum producers around the U.S. In fact, in 1994 the U.S. Department of the Interior Publication named the company’s Gypsum No. 2 mine the largest single gypsum mine in the United States.

In continuation of their dedication to quality products, Harrison Gypsum established Allied Custom Gypsum Inc. in 1987, a customized service aimed at providing customer-based solutions for quality gypsum products. As its own entity, Allied Custom Gypsum Inc. provides custom products and a series of ground gypsum products including flame retardant fillers, animal feed additives, agricultural and turf products, and a high purity food and pharmaceutical grade gypsum to select markets in the industry.

In 2004, Harrison Gypsum LLC commissioned a state of the art plaster mill manufacturing high-end alpha and beta hemi-hydrate materials and industrial plaster formulations for a wide variety of applications.

“We take pride in offering flexible responsive services to our customers, while also maintaining consistent quality standards that produce a premium product,” says Kris Kinder, Vice President of Operations at Harrison Gypsum.

Growing through acquisitions

Harrison Gypsum is content on growing its business through investment in ongoing operations and by acquisitions. The company, which is keen on furthering its success by incorporating new projects to its repertoire, has acquired a wide array of companies in recent years.

In early 2013, the company purchased the assets of Pinnacle Materials LLC’s Eagle Ford Division in South Texas for an undisclosed sum. The acquisition became ACG Materials, which now operates six mines producing aggregate material used to build and maintain roads. The company includes a grinding operation that produces gypsum products for a multitude of end-use applications – including food grade calcium sulfate. Additionally, a state of art plaster plant that produces both alpha and beta hemihydrate plasters which are used in construction products, ceramic products and dental formulations are also included within the division. The company also supplies soil-stabilization products and steel-fabricated hardware manufactured for the energy market.

“We are very excited about this next stage of growth for Harrison Gypsum. Our new Eagle Ford operation will ... help us capitalize on the significant growth occurring in South Texas,” said Russ Harrison, CEO of Harrison Gypsum. “Our expertise in mining aggregates and existing customer relationships should bring significant benefit to ACG Materials.”

Along with acquiring new businesses, Harrison Gypsum is committed to capital investments.

The company has made multiple investments to upgrade to modern mining equipment and improve infrastructure, helping the company expand projects, gypsum reserves and production capacity. The company also utilizes a preventative maintenance program that ensures dependable operation and minimal downtime.

Striving for perfection

Along with acquisitions and company culture, the success of Harrison Gypsum boils down to quality products. The company has created a system that assures every possible measure is taken into account to maintain a consistent and high level of product quality.

The company thoroughly tests deposit sites to ensure the resultant ore is up to par and suitable for use. In addition, selective mining techniques are utilized to ensure recovery of gypsum is maximized and contaminants and substandard rocks are prevented and discarded.

Additional, Harrison Gypsum controls all aspect of mining, processing and packaging operations. This guarantees a high level of quality and product confidence along with customer satisfaction.

- Brightstar, Eldridge and Claure acquire AusencoSupply Chain & Operations

- First Quantum contracts with MECS to cut emissionsSupply Chain & Operations

- Tin production at Andrada Mining reaches record levelsSupply Chain & Operations

- Ternium plans to build US$3.2bn steel plant in MexicoSupply Chain & Operations