How-To: Utilize 3D Mapping in Evaluating Profitability

The name of the game in the mining industry is profitability and the ability to get more out of the resources a company controls is vital for its success.

The use of 3-D mapping is on the rise with companies such as Rio Tinto implementing the innovative software at its West Angelas iron-ore mine in Western Australia.

Rio is banking on the three-dimensional mapping technology to improve the way it digs up commodities as well as helping it cut costs.

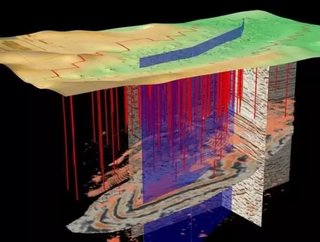

“This technology allows us to quickly and easily view, compare and evaluate data to paint a picture of what’s under the ground. It’s like an ultrasound image of the deposit delivered in real time, something that we could never do before,” says head of innovation John McGagh.

The use of 3D mapping has allowed Rio Tinto to mine 250,000 tons more of iron ore at its Pilbara operations than it would have otherwise. The company has produced a record 139.5 million tons of iron ore in 2014, up 10 percent from a year earlier.

How it work

For Rio Tinto, the 3D mapping incorporates the company’s use of autonomous vehicles and drills rigs to utilize data sent from sensors on the trucks and drills. Based on the data received, the company can analyze the size, location and quality of its ore as it’s mined, therefore helping Rio recover more minerals from deposits.

The use of 3D mapping also provides higher accuracy for miners when it comes to digging. The software has the ability to tell diggers where they're most likely to find high-grade ore and what low-grade material they should dump.

“Ultimately the source of our wealth is the ore body, and you can never know too much,” said Mr. McGagh. “Armed with this detailed information, our operations to recover the ore bodies will be significantly more efficient and effective.”