Penguin ASI Takes Mining Automation to the Next Level

Penguin Automated Systems Inc. is a leading research, development and prototyping company in the field of robotic & Automation solutions. The Company specializes in full service telecommunication enabling the transmission of video, data and voice for control of single or multiple robots and equipment in underground, underwater and space solutions.

First initiated in 2001, Penguin ASI offers a wide range of options in the mining, construction and exploration industries, providing wireless optical networking to underground GPS systems and inertial navigation for positioning. Penguin ASI uses a comprehensive approach to software development, systems integration and field testing to ensure leading edge technologies are supplied to manage all of their client’s needs. By applying existing technology and inventing new ones, Penguin ASI is able to enable the creation of innovative solutions for challenging projects, allowing the Company to be a leading force in the Telerobotics field.

“Most people have shied away or given up from working in the world of teleoperation robots because there wasn’t enough capacity in our communications systems,” explains Dr. Greg Baiden, Chairman and CTO of Penguin Automated Systems Inc. “What we’ve done is worked on solving the problem.”

Robotic implementation

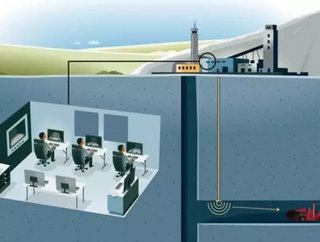

What makes Penguin so unique is the fact their remotely operated vehicles (ROVs) are completely wireless. Typical ROVs require umbilical cords to transmit information between the operator and the vehicle, which poses several problems including limiting the excursion distance of the vehicle and can often lead to entanglement. These factors can restrict the range of movement which is imperative to accomplishing the tasks at hand for exploration, construction and mining. Penguin’s technology does away with the need for cables.

To figure out how to create the perfect mining robots, Dr. Baiden and his team looked at several automobile manufacturing plants around the world and used these manufacturing plants to gain an understanding of how they could design a better ROV.

“We went to all these manufacturing plants and noticed all of them used really advanced computer networks and advanced computing systems,” says Baiden. “The position systems in these assembly lines were done with such precision in terms of surveying because the robots had to move precisely where the car or the piece of car was going to be.”

The Company works at enhancing the technologies that are the core technologies to making robotic mining a reality around the world. They work on advanced computer networks, far more advanced than most businesses and provide these types of networks to their clients. They work on positioning systems because positioning systems that work inside of rock were nonexistent before they began. They also work on software systems that were designed for mining or manufacturing and have modified them to have those systems work together for mining. Unlike companies that have tried to do piece of Telemining, no one has taken the view of trying to accomplish the mine. That’s where Penguin differs from ordinary companies and has become the innovators for the mining industry.

Technologies

Penguin ASI utilizes and develops advanced technologies derived from the Mining Automation Program (MAP). These technologies were designed to create and implement Telemining Systems based on Baiden’s vision for the future of applying robotics with the human touch. However, these technologies are not just for mining.

“These robots have implications not just in mining but civil construction, search and rescue and other things,” says Baiden. “We’ve done mining work in Chile as well as search and rescue work in Canada. We’re constantly doing stuff with this technology outside of just mining.”

The Company’s operations take place at their Penguin Research Centre (PRC) in Naughton, Ontario. Here the Company offers numerous in-house capabilities for prototyping, research, training and constructing. PRC provides custom electronics and manufacturing labs, custom mechanical and construction design centre, along with a composite construction and real time software facility. Their impressive product list has the capacity to provide fully customized precision based models to all of their clients. In addition to engineering functions for the mine of the future, the Company also has their custom research and development side of the business, which allows them to do custom R&D for mining clients, using their foundation technologies.

Future plans

Penguin ASI is constantly striving to enhance the way our world works. They do this by providing solutions to complex and hazardous tasks in various industries such as mining, underwater work and sewer systems. The Company’s groundbreaking technology replaces the existing technologies of today and enables teleoperations for these activities. By applying specialty communications, software and robotic machines, unique electronics, teleautonomy and mobile mechatronics, Penguin ASI is able to achieve results to make for a safer, more productive future, now.

Along with ROVs, the Company is working to create a system that would allow to do underground mapping and reconnaissance in real-time.

“The machines we’ve built are like the Google Car,” explains Baiden. “To survey an underground mine, we can drive a robot in the mine driving at one or two kilometers an hour, collecting massive amounts of information per second. We can reconstruct these tunnels and the inside of building where GPS doesn’t work, and do so with tremendous accuracy.”

The future looks bright for Penguin as the Company is ultimately working on productizing their technologies for the marketplace. As problem solvers for the mining industry, Penguin is helping companies formulate a plan to help solve problems many thought were impossible.

According to Baiden, “We’re turning what problems we’ve solved into products. Our plan for the future is to take this information and technology and be able to market it, diagnose client’s problems and then solve them. “