[VIDEO] Is crowdsourcing the next chapter in innovation?

Canadian miner Integra Gold Corp is looking to leverage the powers of the Internet to find the next multimillion-ounce deposit.

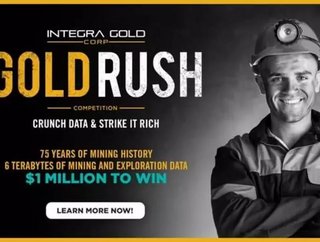

The company has launched the Gold Rush Challenge, an innovative crowdsourcing initiative which will see the company take 70 years of prospecting data from its recently acquired Sigma-Lamaque mine in Quebec and upload it to the Web. Online prospectors will have a chance to analyze and interpret the data to come up with a plan on where they think Integra has the best chance of making a major gold discovery.

The company and a competitions board of advisors will vote on which has the highest probability location for a major gold discovery. The winner will receive a $1 million prize.

"By giving the public access to this data, Integra hopes to tap into the collective brainpower of thousands of participants and save itself years of time and resources to identify high-potential exploration targets we likely wouldn't even know exist," said CEO Stephen de Jong.

"By utilizing external sources this competition allows us to stay focused and disciplined on the work we are doing at our Triangle Zone and Lamaque South property, and at the same time move forward with an exciting exploration target."

• Related content: Is the Internet of Things the next wave for the mining industry?

Rather than utilize the various geological survey and drill-sample reports, the company intends to let people who usually aren’t involved in the exploration process bring creative data analysis methods to the table.

The company believes the crowdsourcing initiative will be a cheap alternative to adding some necessary innovation into the sector.

“The price of whatever commodity, in our case gold, has come down quite a bit,” De Jong said. “There’s just not the excess capital. Now are the times when we really need that innovation.”

This isn’t the first time a mining company has launched a crowdsourcing initiative. Goldcorp held a similar challenge in 2000 that attracted over 1,600 participants and helped the company find roughly $6 billion in gold.

Integra is launching the crowdsourcing initiative with HeroX, a company started by XPrize founder Peter Diamandis.

George Salamis, Integra’s chairman, hopes the project will motivate larger mining companies to do the same.

“We’re prehistoric in how we view data, how we share data, it’s very much an every man for himself industry,” Salamis said. “The rest of the new world of business is heading in a completely different direction, and we have to head in that direction.”

Stay connected! Follow us on Twitter and like us on Facebook

- Luca Mining's Tahuehueto to double throughputSupply Chain & Operations

- Peter Mah named President and CEO of Spanish Mountain GoldSupply Chain & Operations

- SSR Mining acquires 40% stake in Hod Maden from Lidya MinesSupply Chain & Operations

- Gold price nears 7-month peakSupply Chain & Operations